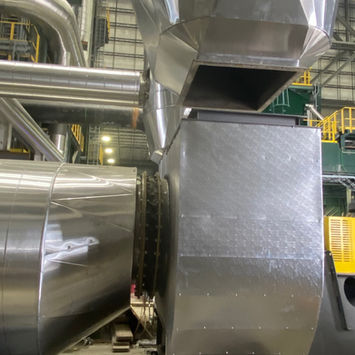

Introducing RAPTOR INDUSTRIAL SERVICES - Your Trusted Partner for Industrial Services Solutions, currently providing services in Arkansas, Tennessee, and East/West of Texas with more that 24 years of industrial experience in refineries, paper facilities, food processing, mills, LNG, etc.

At RAPTOR INDUSTRIAL SERVICES, we specialize in a comprehensive suite of industrial insulation services designed to enhance energy efficiency, reduce operational costs, and ensure optimal performance across various sectors. Our core services include:

1. Industrial Insulation: We excel in providing insulation solutions for pipes, equipment, and tanks. Our team of experienced professionals utilizes cutting-edge techniques and high-quality materials to deliver exceptional results that meet your insulation requirements effectively.

2. Paint: We offer industrial painting services that not only enhance the visual appeal of your equipment but also provide a protective coating against corrosion, chemicals, and weathering. Our skilled painters employ industry-grade paints and adhere to strict quality standards to ensure long-lasting durability and aesthetic appeal.

3. Electric Trace: Our electric trace services help prevent freezing and maintain the desired temperature of your pipes and equipment. With our expertise in electrical heating systems, we can design and install efficient trace heating solutions that protect your assets and optimize operational efficiency.

4. Steam Trace: We specialize in steam tracing systems that efficiently transfer heat to maintain process temperatures and prevent condensation or freezing. Our team has extensive experience in designing, installing, and maintaining steam tracing solutions tailored to your specific applications.

5. Removable Blanket Fabrication: Our skilled craftsmen are adept at fabricating removable insulation blankets that provide excellent thermal insulation and easy accessibility for inspection and maintenance purposes. These custom-designed blankets offer effective insulation while allowing convenient access to your equipment whenever required.

6. Winterization: We offer comprehensive winterization services to protect your critical assets during cold weather conditions. From insulation and weather sealing to heating solutions, we ensure that your operations continue smoothly even in the harshest of winters.

Our commitment to excellence extends beyond our services. We pride ourselves on fostering strong client relationships built on trust, reliability, and open communication. When you choose RAPTOR INDUSTRIAL SERVICES, you gain a dedicated partner who understands your unique requirements and delivers tailored solutions that surpass expectations.

We invite you to explore the possibilities and benefits of partnering with RAPTOR INDUSTRIAL SERVICES. Our team is eager to discuss your specific needs, offer expert advice, and develop a customized solution that addresses your industrial insulation challenges effectively.

Should you require any further information or wish to schedule a meeting, please feel free to contact us at:

info@raptorindustrialserv.com. We look forward to the opportunity of serving Raptor Insulation and becoming your trusted partner for all your industrial service’s needs.

Learn About Our Business

The Full Story

Raptor Industrial Services, established in 2014, proudly serves the thriving industrial landscape of Texas, spanning from the eastern to western regions, with a dedicated presence in the northern areas, where we specialize in providing essential support to refineries, power plants, cold and hot mills, LNG facilities, paper manufacturing plants, and the food processing sector. Our comprehensive suite of services encompasses industrial insulation, paint application, electric and steam trace systems, winterization solutions, and the expert fabrication of removable blankets. With an unwavering commitment to quality and efficiency, Raptor Industrial Services stands as a trusted partner, enabling the seamless operation of critical industrial infrastructure throughout the great state of Texas.

Services

The most important part about picking a hot insulation material is understanding the maximum temperature the insulation will be covering. Components less than 350°F can be covered with off the shelf pre-molded fiberglass. When components are near or above temperatures of 1000°F, silica or ceramic insulation is usually required. It is very important to adhere to manufactures suggestions when picking and installing insulation for hot components.

One of the biggest challenges that industry and manufacturing environments are facing is maintaining suitable noise levels. Noise pollution is a serious problem found in various kinds of industry branches. It is significantly difficult to get used to higher noise levels especially when it can influence the health of your employees on an unconscious level. Long-term exposure to higher noise levels leads to increased stress, insomnia, and other serious health conditions. The noise output from machinery can be overwhelming, almost deafening which is a serious obstacle to maintaining optimal productivity levels. Acoustic insulation can be used to reduce noise on process piping, equipment, duct work etc. providing optimal production levels.

With chilled insulation, keeping the cold in is as important as keeping the heat out. There are many types of insulation used on chilled water pipes. The two most popular are foam glass and rubber insulation or Armaflex. Although a little more difficult to work with than pre molded fiberglass, when installed correctly, these materials do a great job of stopping condensation and preventing energy loss.

Industrial process cooling systems can operate at very cold and even cryogenic temperatures. Creating liquefied natural gas (LNG), for example, requires refrigeration systems to operate at temperatures of -265°F (-165°C) or less. At these temperature extremes, any flaws in the design or installation of the insulation system will quickly become apparent and could potentially damage the system. This is most commonly seen in the form of condensation forming on the outer jacketing or, in particularly bad situations, ice formation on (or in) the insulation. System design flaws also can cause material loss or pressure buildup because the liquefied material reverts back into its gaseous state.This is why it is critical to design any industrial process cooling system to:Limit heat gain.Maintain a consistent temperature.Operate efficiently.To accomplish these objectives, virtually all process cooling applications utilize mechanical insulation systems as a primary method for:Controlling the temperature.Limiting heat gain into the system.Minimizing surface condensation.The most common insulation materials used in non-food/beverage industrial process cooling applications are polyisocyanurate (PIR) foam insulation and cellular glass insulation. Both these insulations offer benefits that system designers can utilize to ensure their systems operate as effectively as possible.PIR insulation is a rigid, polyisocyanurate foam that can be used in applications ranging from extremely low cryogenic temperatures to those operating up to 300°F (149°C). When compared to cellular glass, PIR insulation has a much lower (better) thermal conductivity (K factor), so it can be used at thinner thicknesses while still achieving the desired performance. Additionally, PIR offers mid-level compressive strength, which can help prevent damage to the system under abuse or impact.

Installing a removable insulation blanket designed by Raptor Industrial provides you with these incredible cost saving benefits…1. Reducing Energy CostsMany of our insulation blankets can pay for themselves in less than a year!2. Enable Periodic MaintenanceRemovable insulation allows you to easily conduct periodic inspections and maintenance of equipment and identify and remedy equipment problems and inefficiencies, and maintain cost-efficient operations.3. Prevent Waste and Excess Cost of Hard Insulation for Valves, Flanges, Equipment.With a removable insulation blanket, you can remove the insulation whenever necessary, then easily reinstall it yourself!4. Extend the Life of Equipment & MachineryInsulation covers help protect expensive equipment by reducing exposure to the elements and shielding it from accidental damage.5. Improve Workplace SafetyRemovable insulation covers can prevent direct contact with high-temperature pipes and equipment for greater workplace safety.

Insulating ducts helps the air within stay at the desired temperature.Heat loss through the duct walls is an expected and inevitable drain on the system. Effective thermal insulation of the ductwork reduces this heat loss and helps to minimize energy usage.

Boilers are a vital asset of the process and manufacturing industries globally. Plant managers take every measure to ensure that the boilers are well-functioned and deliver optimal results by following standard guidelines, regular maintenance, and steps to increase the efficiency of the steam boiler. One of the ways to ensure the optimum output of the steam boilers is proper insulation. Insulation is necessary for the safety of the process plant and energy efficiency. Poor boiler insulation is worse than a boiler without insulation. Therefore, it is paramount to assure proper insulation in steam boilers for effective results.What is Insulation in Steam Boilers?In simple terms, insulation helps a steam boiler in storing its thermal energy. Similar to the way a woolen garment retains heat in the body during the winter season. Boiler insulation is used to keep steam boilers and their pressure vessel units hot, prevent radiant heat loss and provide safety and protection to the processing unit and operating team. Proper insulation prevents the surface temperature of steam boiler doors and covers to exceed the required degrees of Fahrenheit. It results in causing danger to the operating personnel working in the vicinity of the boiler surface. It is advisable to insulate any surface that exceeds the temperature by 120°F. Boiler insulation includes insulating,Steam Boiler DoorsSteam Drums CoversSteam Boiler PipingBoiler piping insulation is important for its operation. However, it is often overlooked and may lead to significant heat loss. Proper insulation in team boilers results in energy conservation, plant and employee safety, and acceleration in efficiency for process operations.

The total cost of replacing industrial equipment often adds up to more than the purchase price of a new machine because there’s the installation cost, retraining workers, possible downtime, and the disposal of old equipment to account for. Supporting equipment longevity is a critical aspect of managing industrial assets, and insulation helps.When a machine operates on the edge of its functional boundaries (outside its optimal performance range), it wears out sooner and requires more frequent maintenance. Insulation encourages asset longevity by preventing waste heat from escaping, so the equipment can maintain ideal performance longer.Consider an uninsulated boiler that needs to work constantly to overcome heat loss. Running at the limit of its operability stresses components and leads to frequent servicing. On the other hand, an insulated boiler (one that operates within a reasonable range) will last longer as its parts won’t require as much maintenance or repair.

No insulation system, hot or cold, would be complete without the metal jacketing. Metal jacketing helps protect the insulation system from damage, including helping protect the vapor retarder from damaging UV light exposure and animal assault.The most common metal jacketings used in North America are stainless steel and aluminum. Stainless steel jacketing is more resistant to corrosion, which makes it the more common choice in corrosive environments such as near or on the ocean. Stainless steel jacketing also is more resistant to fire. Yet in most applications, aluminum jacketing is the preferred material because it is a less costly alternative while still providing acceptable corrosion resistance.

Contact

We are committed to all of our clients, and look forward to working with you. Questions, comments or special requests? We would love to hear from you.